In today’s competitive business environment, companies are constantly seeking ways to optimize operations and cut costs. One area often overlooked is the process of pallet wrapping. While hand wrapping pallets might seem like a budget-friendly option, it can actually end up costing your business more in the long run. Investing in a machine pallet wrapper offers significant financial and operational benefits.

Here are five reasons why making the switch is a smart investment:

1. Inconsistent Film Usage

Hand wrapping pallets often leads to inconsistent application of stretch film. This inconsistency results in uneven coverage, leading to film waste and increased costs. Without the precision of a machine, it’s easy for employees to use more film than necessary, driving up material expenses over time.

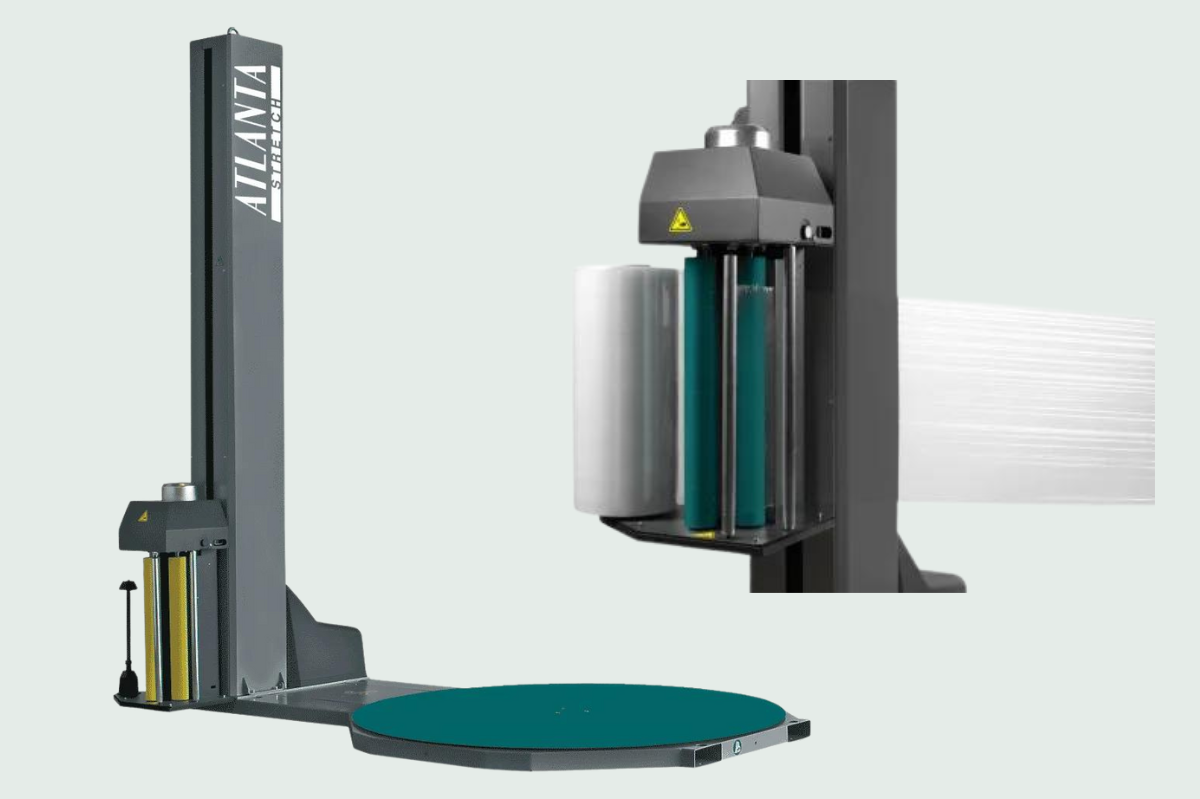

Machine pallet wrappers, on the other hand, apply film with uniform tension and coverage every time. This ensures optimal use of the film, significantly reducing waste. By maximizing the efficiency of film usage, you can save a substantial amount on material costs. Over time, these savings can add up, making a machine wrapper a cost-effective solution.

2. No Pre-Stretch Capabilities

One of the major advantages of machine pallet wrappers is their ability to pre-stretch the film. Machines can stretch film up to 300%, allowing you to cover more area with less material. In contrast, hand wrapping typically achieves only about 100-150% stretch, leading to higher film consumption and increased costs.

By leveraging the pre-stretch capabilities of a machine, you can significantly reduce the amount of film needed per pallet. This not only lowers your material costs but also contributes to a more sustainable operation by minimizing plastic waste. The reduction in film usage translates directly into cost savings, providing a quick return on your investment.

3. Higher Labor Costs

Hand wrapping is a labor-intensive and time-consuming process. Employees spend a considerable amount of time wrapping pallets, which could be used for more productive tasks. Additionally, the physical strain of hand wrapping can slow down the process, further increasing labor costs.

Machine pallet wrappers operate much faster than manual labor, wrapping pallets efficiently and consistently. This frees up employees to focus on other critical tasks, enhancing overall productivity. By reducing the time and effort spent on wrapping pallets, you can lower labor costs and improve operational efficiency. The increase in productivity and reduction in labor expenses can have a significant positive impact on your bottom line.

4. Increased Risk of Injuries

Hand wrapping involves repetitive motions that can lead to musculoskeletal injuries. Employees are required to bend, twist, and stretch repeatedly, which can cause strain and injury over time. These injuries not only affect the health and well-being of your workforce but also result in higher medical expenses and lost workdays.

Investing in a machine pallet wrapper eliminates the need for repetitive manual labor, reducing the risk of workplace injuries. A healthier workforce means fewer medical expenses and less downtime due to injuries. By providing a safer work environment, you can enhance employee morale and productivity while reducing costs associated with workplace injuries.

5. Potential for Damaged Goods

Improperly hand-wrapped pallets are more likely to shift or collapse during transit, leading to product damage. Damaged goods not only result in financial losses but also impact customer satisfaction and your company’s reputation. Ensuring that pallets are securely and consistently wrapped is crucial to preventing such issues.

Machine pallet wrappers provide a reliable and secure wrap every time, minimizing the risk of pallet failure during transit. This consistency helps to protect your goods, reducing damage and return costs. By ensuring that your products arrive safely at their destination, you can maintain customer satisfaction and protect your brand reputation.

Switching to a machine pallet wrapper is a strategic investment that offers numerous benefits over hand wrapping. By ensuring consistent film usage, leveraging pre-stretch capabilities, reducing labor costs, minimizing the risk of injuries, and preventing product damage, machine pallet wrappers can significantly reduce your operational expenses. In the long run, this investment will pay for itself through cost savings and improved efficiency. Embrace the advantages of automation and make the smart choice for your business today.