Step-by-Step Guide to Properly Strapping Pallets

Strapping pallets correctly and using the right pallet strapping equipment is essential for securing goods during transport and storage, preventing damage and ensuring safety. In this guide, Just In Time Packaging will detail the best pallet strapping practices to help you achieve secure and stable loads every time.

Why Proper Pallet Strapping Matters

Properly strapping pallets ensures that your shipments remain intact from departure to arrival. Poorly strapped loads will naturally shift during transit, leading to damage, potential lossesand even safety hazards for handling personnel. By following effective pallet strapping methods, businesses can improve efficiency and reduce waste.

At Just In Time Packaging, we understand the importance of high-quality strapping solutions. With over 30 years of experience, we can provide expert advice and quality products to help businesses like yours streamline their packaging processes.

How to Strap a Pallet in 5 Easy Steps

Step 1: Choose the Right Pallet Strapping Equipment

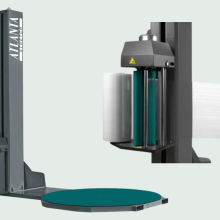

Selecting the right pallet strapping equipment depends on the weight and type of goods being secured. Options include:

- Manual Strapping Tools – Ideal for small-scale operations that require flexibility.

- Semi-Automatic Strapping Machines – Increase efficiency with easy application.

- Automatic Strapping Machines – The best choice for high-volume packaging operations.

Step 2: Position Your Load Correctly

Before applying strapping, ensure your goods are stacked evenly on the pallet. Avoid overhanging boxes, as they can make strapping less effective and increase the risk of damage.

Step 3: Apply the Strapping

Wrap the strap around the pallet load horizontally or vertically, depending on the stability required. Pull the strap tight using a tensioner tool to keep the load secure. If using manual straps, use a sealer and metal seals to lock the strap in place. If using plastic strapping, a heat or friction welder can create a strong seal.

Step 4: Test Stability

Test the stability of the strapped pallet by gently applying pressure to different sides. If the load moves significantly, reapply tension or add additional straps as needed.

Step 5: Label & Prepare for Transport

Once the pallet is securely strapped, label it appropriately to ensure correct handling during shipping. Proper labelling also helps reduce the risk of misplacement.

Best Pallet Strapping Practices for Maximum Security

To enhance your strapping efficiency, follow these best pallet strapping practices:

- Use high-quality strapping materials suited to your load weight

- Always inspect strapping equipment for wear and tear before use

- Apply corner protectors to prevent strap damage on delicate goods

- Use multiple straps for heavy or irregularly shaped loads

- Train employees on effective pallet strapping methods to ensure consistency

Secure Your Shipments with Confidence

Just In Time Packaging offers a wide range of strapping solutions to help you meet your packaging needs, from manual tools to advanced strapping machines. For personalised advice on choosing the right pallet strapping equipment, contact us today.